Use superabsorbent polymers for:

Energy & Infrastructure Drilling

Environmental Remediation

Medical Applications

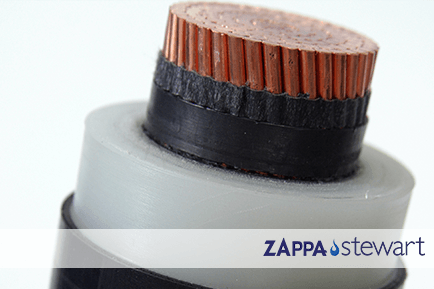

Wire & Cable Applications

Consumer Products

Superabsorbent Polymer Applications

Elastomer Manufacturing

Absorbent Pad Application

Environmental Remediation

Zappa-Stewart Advantages:

|

|

|

| Ready Inventory | Formulated SAP | Tech Consultation |

Superabsorbent Polymers are around us being used everywhere*.

*use desktop for better display